Project

Valorization of digestate at Sütaş, Turkey

Sütaş Group is one of the largest dairy producers in Turkey. At three locations, the company manages the entire dairy chain, which includes cow breeding and milk production, cattle feed production, dairy products manufacturing and waste management. The company operates 18 biogas digesters for the processing of wastes. Biogas is converted into electricity, steam and heat. Yuniko expert’s activities:

- Technical assistance to the Waste and Energy Division.

- Operations of the biogas plants.

- Improvements of waste water treatment.

- Feasibility project for the production of organic fertilizer on basis of the digestate from the biogas plants.

Project

DSI® rainwater infiltration and ground drainage at Apeldoorn, Netherlands

DSI stands for Düsen Saug Infiltration, a technology also known as Fast High Volume Infiltration (FHVI). The principle of the technology is that water is infiltrated in special layers in the ground. These special layers are identified by FHVI. For that reason it is possible to infiltrate more water than with traditional infiltration. The FHVI technology is very good equipped for the rising problem of rainwater in urban environments.

The EU recognises that this technology can be used in many places. They awarded the project through the LIFE programme. In the municipalities of Apeldoorn and Werder (Germany) demonstration projects are realised.

In Apeldoorn, between 2019 and 2022, some 150 infiltration wells will be constructed according to the FHVI technology and, as a result, rainwater can flow back into the soil in a short time instead of running off to the sewer. The sewer system will thus not be overloaded and flooding of streets is prevented.

Yuniko expert’s activities:

- Coordination of the project organization, the beneficiary, the LIFE programme and the Steering Group

- Coordination of the public relations of the project

- Contacts with other interested parties in The Netherlands and abroad.

Project

Anaerobic fermentation at KABI, Kosovo

KABI is a modern dairy plant in Kosovo, located in Glijan. The company produce a variety of local products: fresh milk, yoghurt, sour cream, white cheese, feta cheese, ayran, and cream. In 2018, KABI has started a modernization program which includes the installation of a new production line for feta cheese, a quality improvement program and the construction of an innovative anaerobic fermentation plant. This technology converts waste streams into biogas and reduces the pollution of the environment. The biogas is a valuable resource for the production of hot water for the dairy processes.

Yuniko expert’s activities:

- Technical and economic feasibility study.

- Design and construction of the anaerobic fermentation plant, including tank construction, biogas storage and processing, installation of electromechanical equipment, telecom and data monitoring.

- Design and construction of civil works, piping, cabling etc.

Project

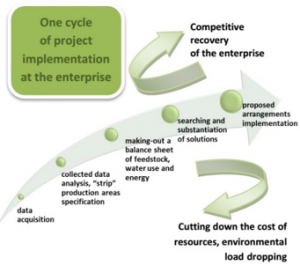

Process optimization for dairy industries

Balkan countries

Yuniko is active in the food industry of several Balkan countries. Many milk processors are among our customers. We provide solutions for various issues related to the use of water, the use of energy and the quality of the production process and the utilization of resources. We provide solutions for the treatment of effluents from dairy plants with capacities between 10,000 to 200,000 liters of milk per day. Further, we develop in-process solutions based Resource Efficient and Cleaner Production (RECP), such as recovery of whey, optimization of CIP installations and energy efficiency.

Yuniko is active in the food industry of several Balkan countries. Many milk processors are among our customers. We provide solutions for various issues related to the use of water, the use of energy and the quality of the production process and the utilization of resources. We provide solutions for the treatment of effluents from dairy plants with capacities between 10,000 to 200,000 liters of milk per day. Further, we develop in-process solutions based Resource Efficient and Cleaner Production (RECP), such as recovery of whey, optimization of CIP installations and energy efficiency.

Yuniko expert’s activities:

- Optimization of CIP systems, reducing water consumption, chemicals consumption and energy use

- Improvements of wastewater treatment for reduction of energy consumption.

- Feasibility studies for whey recovery, whey concentrate production, wastewater treatment, biogas generation.

- Technical plan for reduction of the wastewater flow, the reduction of product losses, improvement of the milk quality by technical measures for the milk cooling plants etc.

- Procurement of equipment and new systems.

- Training of industry experts for environmental management and quality management

Project

Al Manara: Drinking Water Production Plant

Khartoum, Sudan

In 2010 the Dutch Development Bank (FMO), in cooperation with other international financing organizations, invested in a drinking water production plant in Khartoum, Sudan. The capacity of the plant is intended to be 200,000 m³ per day. The arrangement with the government of Sudan is that they buy the drinking water of Al Manara. The government then sells the drinking water to the local people. The raw water is extracted from the Nile.

The overall Omdurman Water Supply Project implied the construction of a completely new drinking water treatment plant in Khartoum, with a capacity of 200,000 m³ per day, transmission mains, a connection to the new storage reservoir (40,000 m³), a booster station at Al Thoura, and the connection to the existing storage in Al Gamayir.

Yuniko expert’s activities:

- Director in the Board of Directors

Project

Optimization of Sludge Treatment in Tilburg

De Dommel Water Board

The Tilburg Waste Water Treatment Plant was facing operational issues and was looking for economic optimization. Yuniko’s approach for Data Economics was applied and resulted in significant reduction of operational cost with improved quality by means of monitoring and validation of process data.

Yuniko expert’s activities:

Project

Dairy wastewater treatment at Bylmeti

Bylmeti dairy company

Bylmeti dairy company is among the 5 largest milk processors of Kosovo. They have a modern processing plant, they produce for the Kosovar and regional markets and employ almost 50 people. It is the only dairy processor which is provided with a wastewater treatment plant. However, milk losses, cleaning water (CIP) and whey are discharged to this treatment plant.

Yuniko expert’s activities:

- Aeration system, including blowers and plate aerators

- Analysis of the dairy plant and inventory of waste flows, cleaning process and energy consumption

- Improvements of wastewater treatment

- Technical plan for reduction of the wastewater flow, the reduction of product losses, improvement of the milk quality by technical measures for the milk cooling plants etc.

Project

Aerobic treatment of dairy wastewater in Macedonia

Sentis AG Dairy Company

Sentis AG is a dairy company in Macedonia and producer of milk, yoghurts and cheeses for markets in Macedonia and the region. Sentis started to treat the wastewater some years ago. It was chosen to install a Moving Bed Biofilm Reactor (MBBR). The wastewater treatment process follows a cycle of aeration-sedimentation-discharge. The effluent standards were:

- BOD5 (Biological Oxygen Demand) of 25 mg O2/l

- COD (Chemical Oxygen Demand) 125 mg O2/l

However, the results of treatment plant were disappointing and re-construction of the wastewater treatment plant is necessary.

Yuniko expert’s activities:

- Analysis of the wastewater situation and the discharge of effluents

- Feasibility study for the re-construction of the existing wastewater treatment plant

- Development of the re-construction plan for the existing WWTP